Revolutionize your maintenance operations with Maintainsoft's AI Maintenance CoPilot. Get intelligent predictions, automated insights, and smart recommendations to prevent equipment failures and optimize maintenance efficiency.

No credit card required

Join thousands of teams using MaintainSoft

87%

Reduction in unplanned downtime

65%

Decrease in maintenance costs

92%

Improvement in prediction accuracy

78%

Increase in equipment lifespan

Our AI Maintenance CoPilot leverages machine learning algorithms to analyze equipment performance patterns, historical maintenance data, and operational conditions. This intelligent system provides proactive insights that help maintenance teams prevent costly breakdowns and optimize resource allocation.

Advanced AI models continuously monitor equipment health indicators, vibration patterns, temperature fluctuations, and performance metrics. The CoPilot identifies anomalies and predicts potential failures weeks or months in advance, enabling proactive maintenance scheduling.

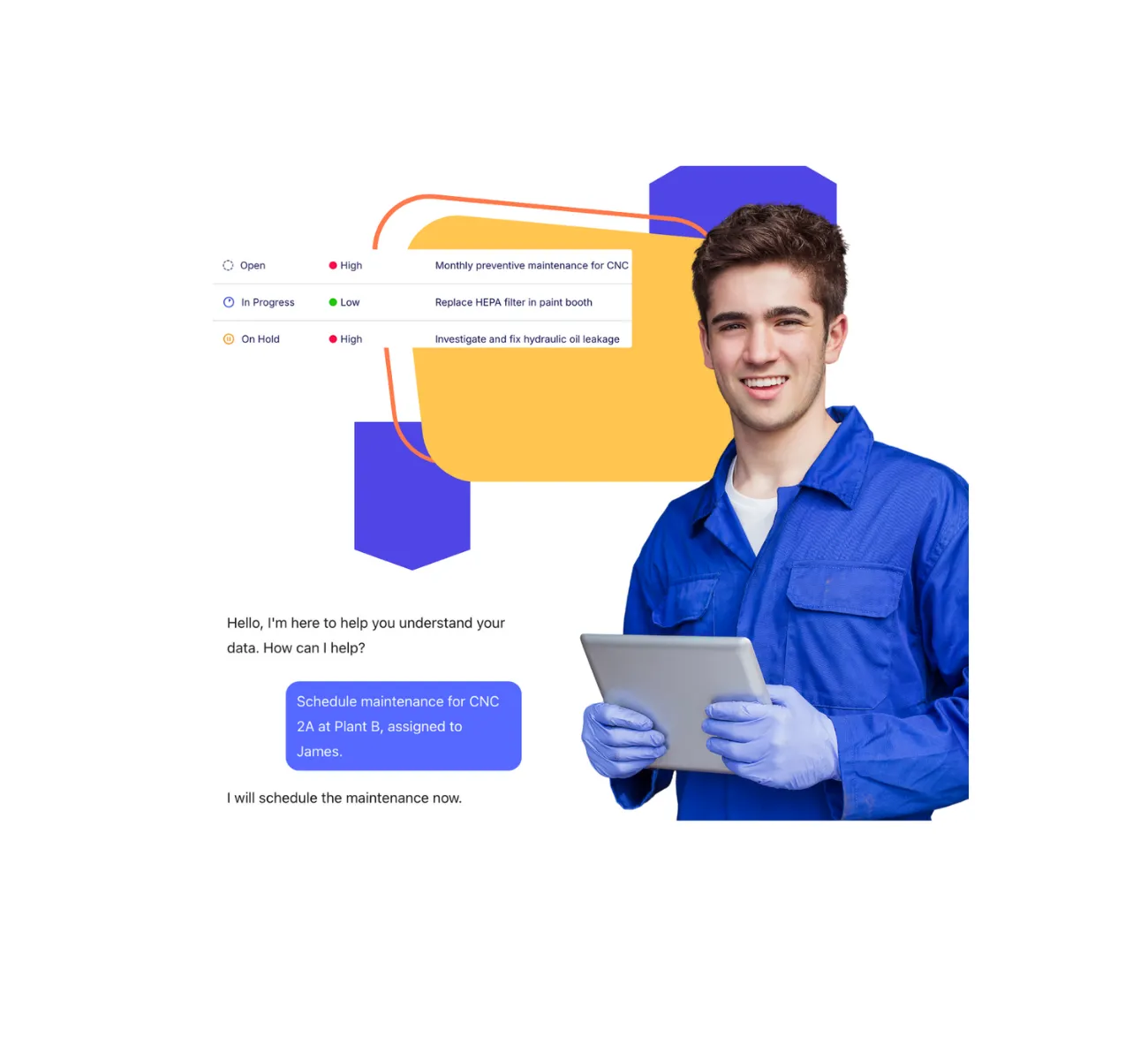

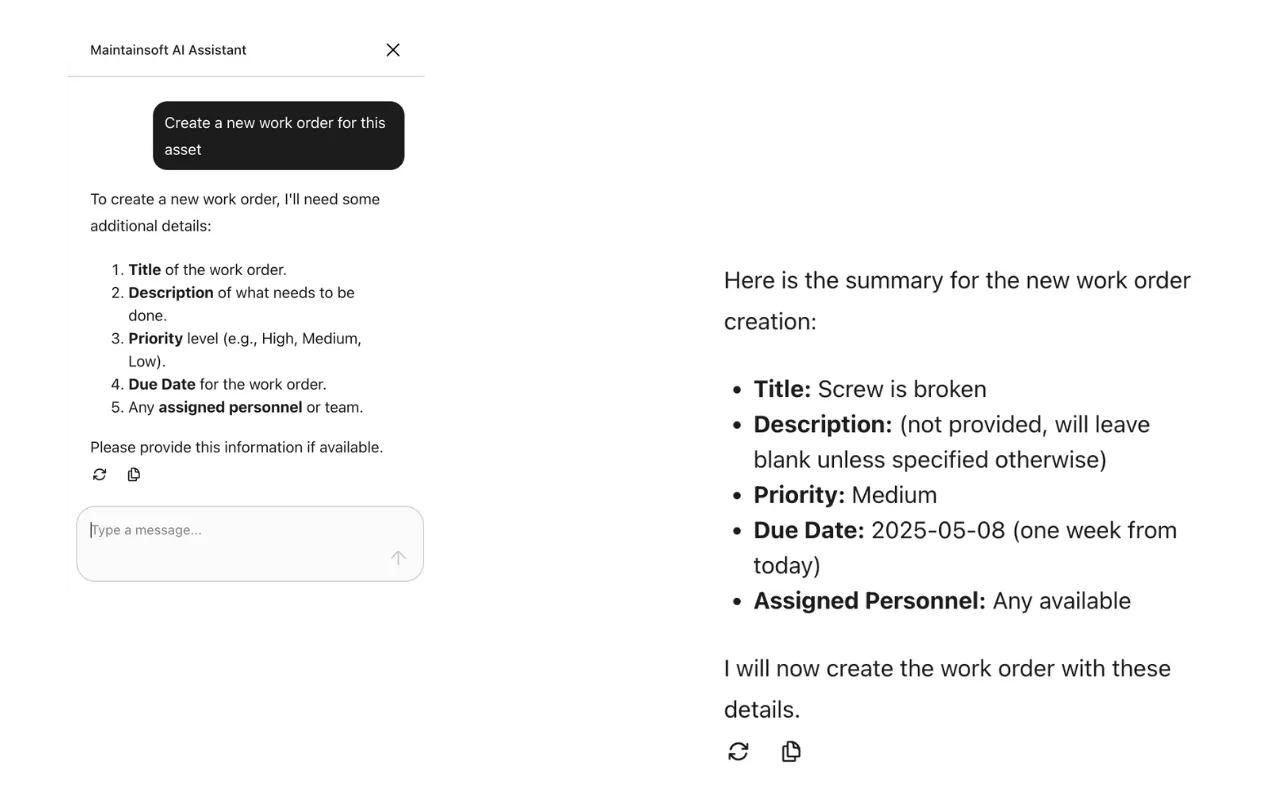

The AI CoPilot automatically generates optimized work orders based on predictive insights, equipment priority, technician availability, and parts inventory. Smart scheduling algorithms ensure critical maintenance tasks are prioritized while maximizing team efficiency.

Interact with your maintenance data using natural language queries. Ask questions like "Which assets need attention this week?" or "What's causing repeated failures in pump station 3?" and receive instant, actionable insights from your AI CoPilot.

AI CoPilot Capabilities

Predictive Analytics

AI analyzes equipment data patterns to predict failures before they occur.

Smart Recommendations

Receive intelligent maintenance suggestions based on real-time equipment conditions.

Automated Diagnostics

AI-powered diagnostic tools identify root causes and optimal repair strategies.

Resource Optimization

Optimize technician scheduling and parts inventory using AI insights.

AI Maintenance CoPilot is an intelligent assistant that uses artificial intelligence and machine learning to analyze equipment data, predict failures, and provide actionable maintenance recommendations. It acts as a virtual expert that helps maintenance teams make data-driven decisions.

Our AI CoPilot analyzes historical maintenance records, sensor data, equipment performance metrics, and operational patterns using advanced machine learning algorithms. It identifies patterns that precede equipment failures and alerts maintenance teams before problems occur.

The AI CoPilot can monitor virtually any industrial equipment including pumps, motors, compressors, HVAC systems, manufacturing equipment, fleet vehicles, and facility infrastructure. It adapts to different equipment types and learns their unique operational patterns.

Our AI CoPilot achieves over 92% accuracy in failure predictions when provided with adequate historical data and sensor inputs. Accuracy improves over time as the AI learns your specific equipment patterns and maintenance practices.

While the AI CoPilot works best with IoT sensors and real-time data feeds, it can also provide valuable insights using existing maintenance records, work order history, and manual inspections. We offer flexible integration options based on your current infrastructure.

Initial insights can be generated within 30 days of implementation using historical data. Predictive accuracy improves significantly after 3-6 months as the AI learns your equipment patterns. Full optimization benefits are typically realized within 6-12 months.

Track all your asset maintenance in one intelligent system, powered by AI insights and designed for teams that demand excellence.

Instant visibility

Smart predictions

Work anywhere

No credit card required

Join thousands of teams using MaintainSoft

Join 200+ maintenance teams worldwide - No credit card required

Leave a message I’ll get back soon