Predict issues, auto-assign tasks, and get smart insights with our AI engine.

No credit card required

73%

Reduction in unexpected equipment failures

42%

Decrease in maintenance planning time

68%

Improvement in work order completion rates

35%

Reduction in maintenance costs

Leverage artificial intelligence to optimize your maintenance operations. Our AI capabilities help you prevent equipment failures, streamline work allocation, and make data-driven decisions.

Stop reacting to breakdowns and start preventing them. Our AI algorithms analyze equipment data, usage patterns, and maintenance history to predict when failures might occur, allowing you to schedule maintenance before problems arise.

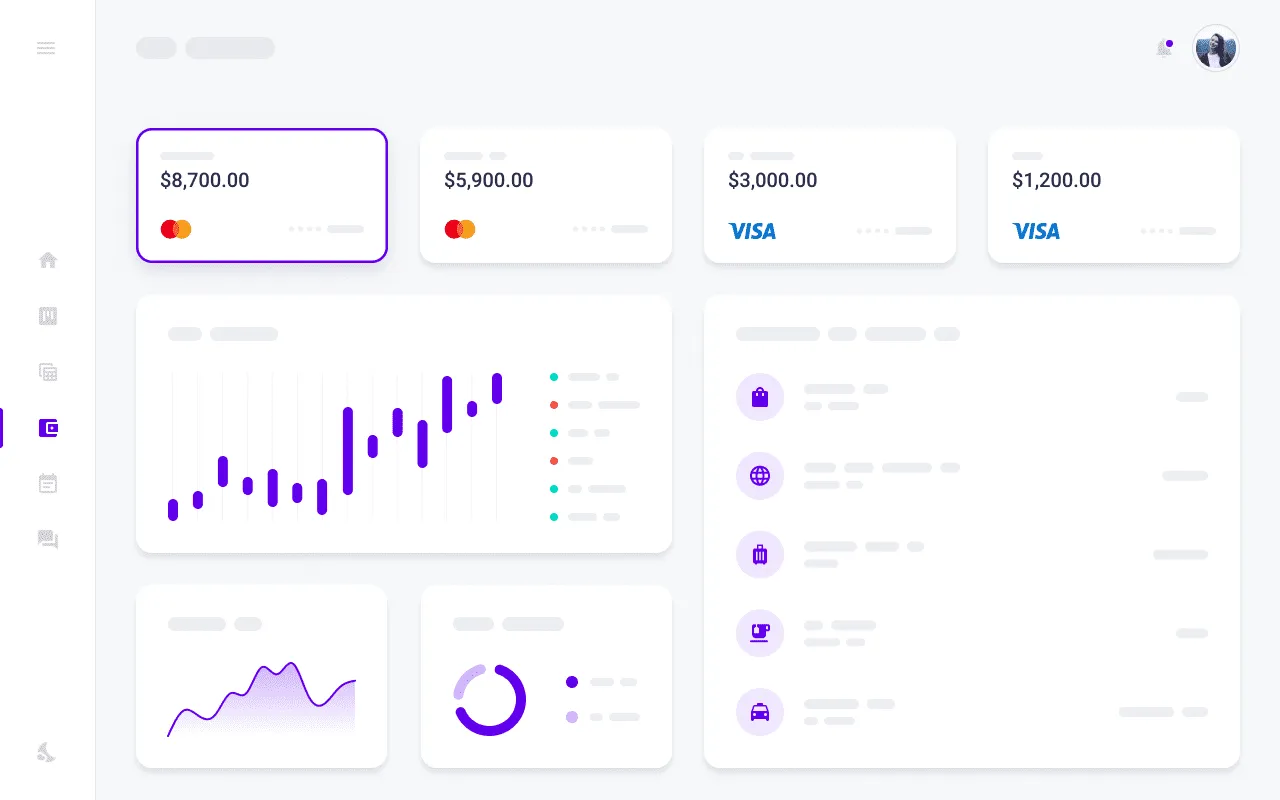

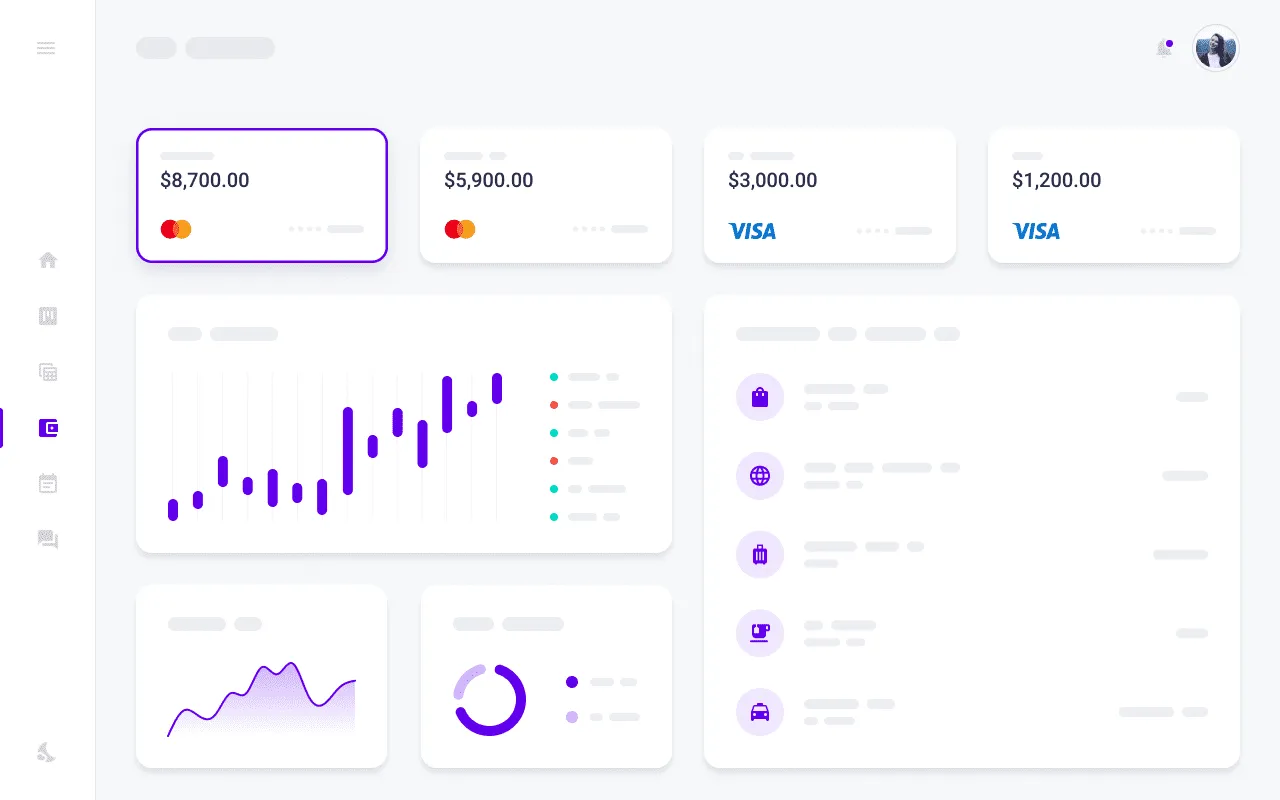

Let AI handle the logistics of assigning work orders. The system considers technician skills, certifications, location, and current workload to automatically route tasks to the most appropriate team member.

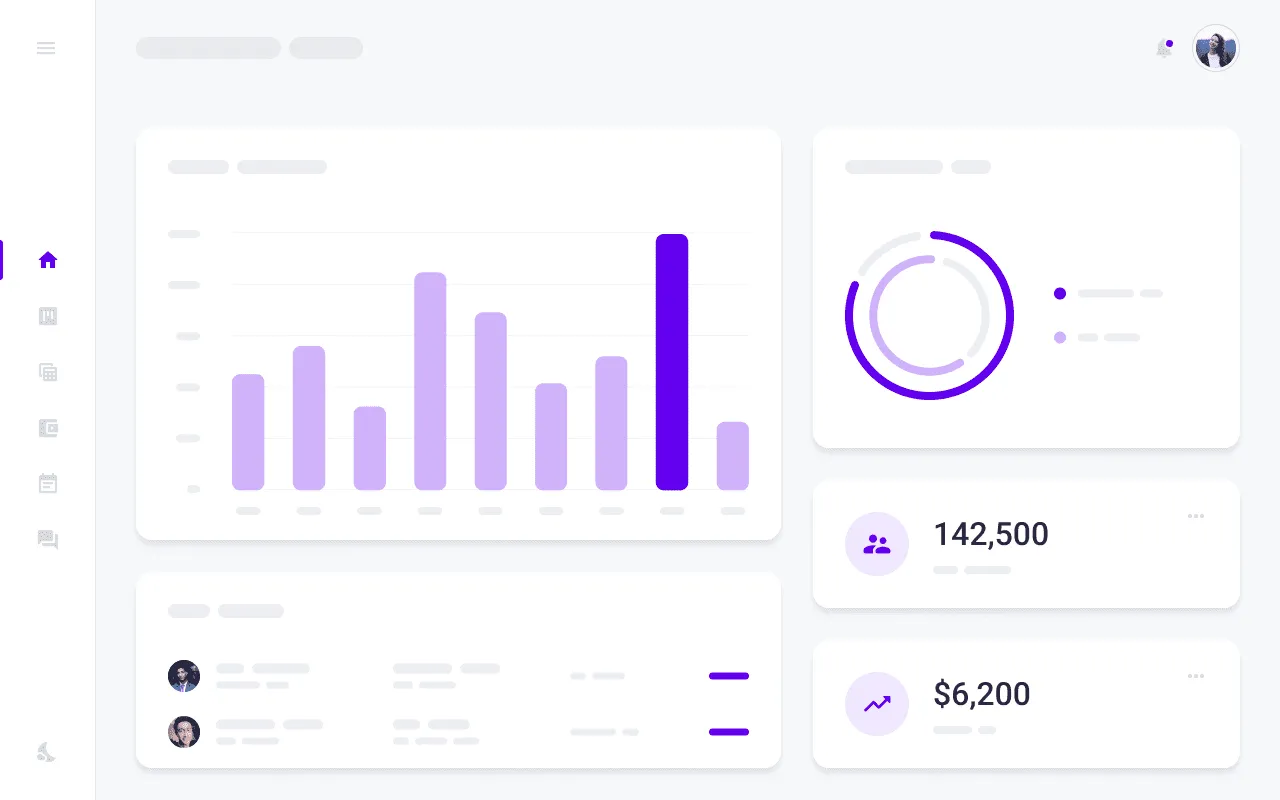

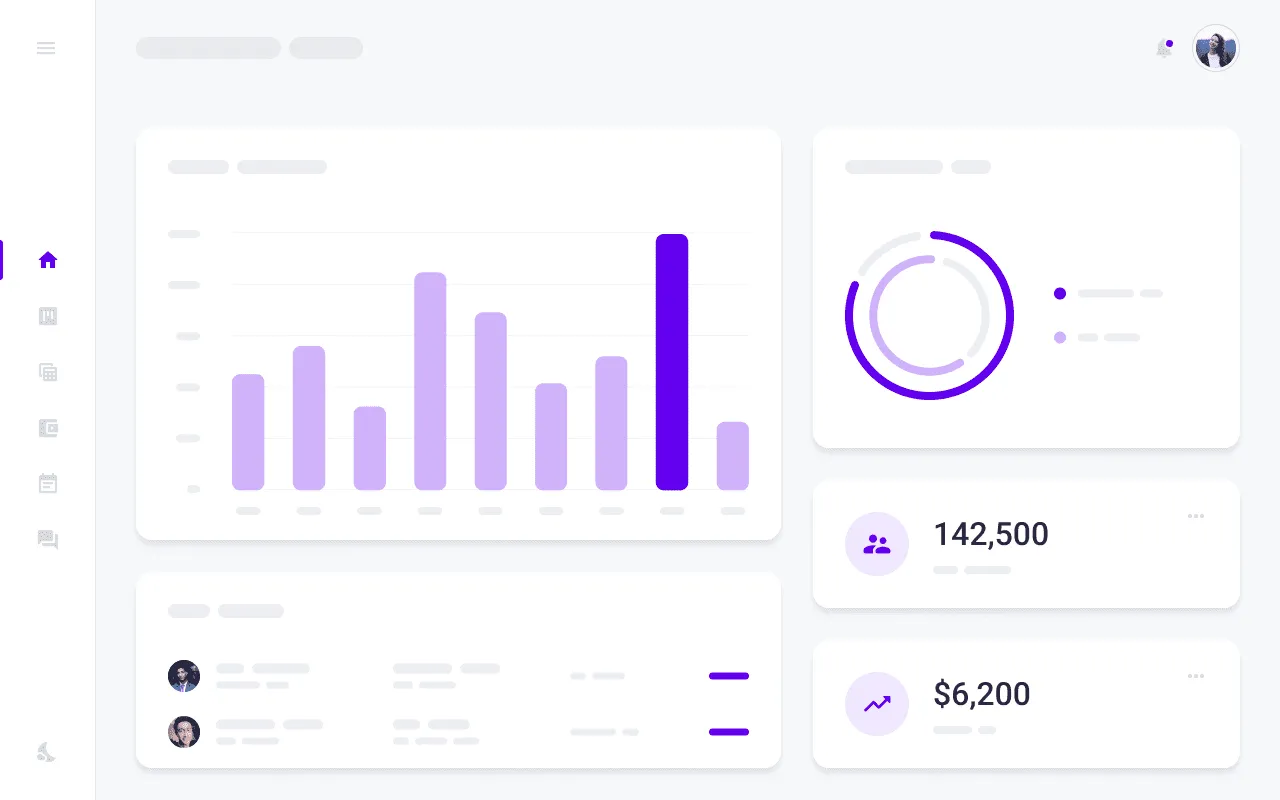

Transform raw maintenance data into actionable intelligence. Our AI-powered reporting tools identify trends, highlight improvement opportunities, and provide recommendations to optimize your maintenance operations.

Key AI Features

Predictive Maintenance

AI algorithms analyze equipment data to predict potential failures before they occur.

Smart Work Order Assignment

Automatically assign tasks to the best-qualified technician based on skills and availability.

Automated Reporting

Generate intelligent insights and recommendations from your maintenance data.

Natural Language Processing

Use conversational AI to quickly create and update work orders and reports.

Our AI predictive maintenance system uses machine learning algorithms to analyze data from equipment sensors, maintenance history, and operational patterns. It identifies anomalies and developing issues before they cause failures, allowing you to schedule maintenance proactively rather than reactively.

Yes, the AI system continuously learns from your specific equipment and maintenance data. The more history it has to analyze, the more accurate its predictions become for your particular assets and operating conditions.

Smart work order assignment considers multiple factors including technician skills, certifications, location, current workload, and task priority. This ensures that work orders are assigned to the most qualified available technician, reducing completion time and improving first-time fix rates.

Automated reporting provides insights such as equipment reliability metrics, maintenance cost analysis, technician productivity data, inventory optimization recommendations, and predictive maintenance opportunities. These insights help you make data-driven decisions to improve your maintenance operations.

Track all your asset maintenance in one system, right at your fingertips.

No credit card required

Leave a message I’ll get back soon